Well, it was well worth the effort!

The cam ring was fitted to the maggie on my '51 plunger.

before this, I had the bike dyno tested, and the carburation was set up spot on!

I had the SRM timing wheel in place, and strobe checked the timing. However, it showed a big problem; LH pot was 34 BTDC, RH pot was 40 BTDC! The dyno run was abandoned at this stage, and I took the bike home to "sort 'er out"!

The frustrating thisn is that the maggie had been done up before the run (by others). I talked to them, and they confirmed that new bearings had been installed, and shimmed correctly. I couyld not measure ant run-out on the shaft, so decided to focus on the cam ring to get the result required.

I bought a NOS cam ring, but when installed, there was 8 degrees difference between the pots!

This was too valuable to modify, so I had a rusty old ring, and worked on it. It cleaned up nicely, but I had 0.003" points gap variance, and 6 degrees difference in firing points.

I kept grinding away the profile on the side with the wider points opening until both sides were 0.012", then focused on carefully advancing (removing) the lip which opens the points until, using a 0.0015" feeler gauge, both pots opened at the same point before TDC

It took me about 2 1/2 hours to get both pots firing identically.

I had the SRM timing disc set up on their primary drive nut.

Then I fired up the engine, and checked the timing with a strobe light; they were both firing at the same point BTDC! At idle, it was 6 degrees BTDC. . The full advance was 32 degrees BTDC

Now, back to the dyno!

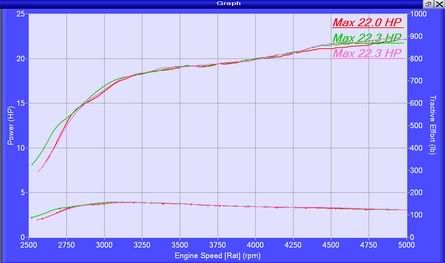

On the previous run, we achieved 18.7 BHP(rear wheel). Now we had 19.7, and more torque!

We advanced the timing to 34 degrees; this was too much - power dropped off.

The best result was 31 degrees BTDC. It resulted in 20.2 HP, and the widest spread of torque.. This equates to 5 degrees BTDC at idle so if you install a SRM kit, you can check your bike easioly. Note that i slotted my 3 maggy mounting holes, and had a total of 18 degrees variance available just by moving the mag body!

Interestingly, the '54 GF produced 22.2 HP with a different curve profile. Both bikes have 365 cams, 7.25 : 1 pistons, and 276 carbs. The other point is that the '54 performed best at 30.5 BTDC

The bikes are noticably smoother and more power ful to ride.

Stay tuned for the '51 Rigid, '56 Road Rocket, '61 RGS replica and '60 Super Rocket!

Richard